About this Event

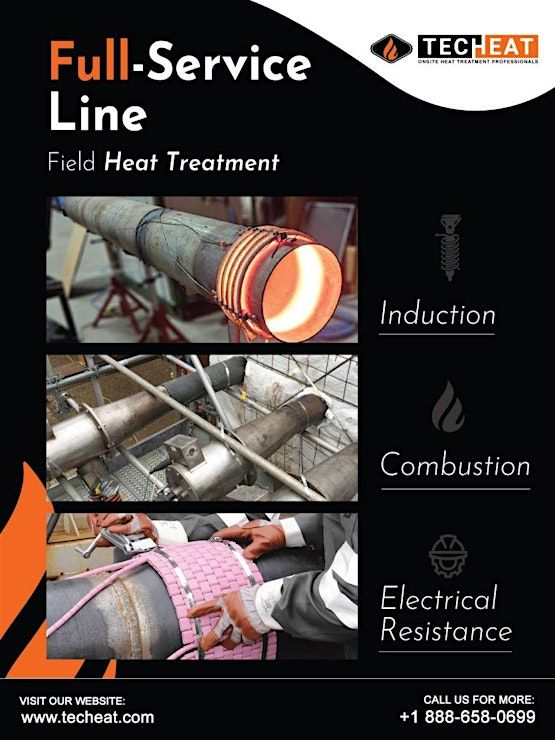

Field Heat Treatment (FHT), also known as Local Heat Treatment (LHT), allows for precision metallurgical processes to be performed on-site, eliminating the need for furnaces or extensive disassembly. This article explores the three primary heating methods—electrical resistance, induction, and high-velocity combustion—and explains how each is applied to field processes such as welding preheat, dehydrogenation (DHT), post-weld heat treatment (PWHT), solution annealing, refractory dry-outs, nut removal, and turbine hub disassembly. With insights into temperature control, safety, and evolving digital systems, it highlights how modern heat treatment technologies ensure integrity, efficiency, and compliance across heavy industries

Presented by: Bruce Stewart

Mr. Stewart has been directly involved in the heat treatment industry starting as a field technician trainee in 1991. During his career he has worked in a variety of safety, technical, supervisory and management capacities within the field heat treatment industry. He helped develop and delivered theoretical and hands on training of Field Heat Treatment Technicians across Canada for 16 years with the Quality Control Council of Canada.

Technical training includes Field Heat Treatment Journeyperson, CWB Welding inspection (Nait), Materials and Engineering Technologies (M.E.T 202 Nait), Management and supply train procedures, past NCSO certification (ACSA). Mr. Stewart is a voting member on the American Welding Society D10 Subcommittee on Local Heat Treating of Pipework.

His current position as Competency Manager at Technical Heat Treatment includes program development, HSEQ management and industry representation including today’s presentation.

Event Venue & Nearby Stays

TECHEAT - Technical Heat Treatment Services Ltd., 1303 70 Avenue Northwest, Edmonton, Canada

CAD 12.06 to CAD 38.74