About this Event

Hands-On Improvement kata for Leaders & Practitioners. Learn the two fundamental behavior patterns at the core of Toyota kata:

- The Improvement kata and the Coaching kata driven by

- The 5-Question Coaching Dialogue and Rapid PDCA cycles.

This is an innovative management system that provides the means to achieve two equally important objectives:

- Rapid PDCA Cycles – a methodology to achieve challenging objectives that are currently beyond a team’s ability to reach, and…

- The 5-Question Coaching Dialog – Developing managers and leaders as coaches for creating a culture of continuous improvement, adaption, and innovation. This is done through simple, easy-to-teach, time-efficient, daily routines.

This 1-Day workshop provides a unique mix of theory and hands-on practical activities to teach participants four steps of Toyota Kata:

- Understand the Direction

- Grasp the current Situation

- Establish next Target Condition

- PDCA towards the Target Condition

The four steps of the Improvement Kata are a model of scientific thinking and acting that is similar to other models of the human creative process. What is different is that each step includes structured practice routines, which make the pattern actionable and teachable.

The Improvement Kata process methodology will encourage teams to generate improvement ideas, build rapport, and incorporate prototyping and experimentation to solve problems and challenges. Each round of Quality Lab Simulation will reveal a true nature of collaboration. It will illustrate how each member of the Team innovates and emphasizes the importance of diverse perspective.

The Improvement Kata is for the Learner and the Coaching Kata is for the Coach. To make the scientific Improvement Kata pattern a habit in an organization, managers coach their people in the Improvement Kata routines a little bit every day. The Coaching Kata is a protocol for how to do that. The practice routines of the Improvement Kata and the Coaching Kata are a regimen for developing practical scientific skill and mindset that any manager can use.

Workshop Objectives

Upon completion, this workshop will:

- Understand principle behavior patterns at the core of the Toyota Kata methodology

- Provide participants with the knowledge of fundamental routines, mindset, and behavioral routine practices of Toyota Kata

- Enable participants to experience the behavioral routines of Toyota Kata including the Improvement kata and the Coaching kata through interactive, hands-on experience

- Equip attendees to explain how Toyota Kata is different from other management systems

- It will help participants to develop a sustaining culture of Continuous Improvement in their organization

- It will demonstrate how leaders and managers can create a lasting culture of Continuous Improvement through simple, easy-to-use, and time-efficient daily routines

- Develop familiarity and confidence in applying two essential Toyota Kata methods:

Rapid PDCA (Plan-Do-Check-Act) Cycles and the 5-Question Coaching Dialogue

Who Should Attend

Office and Shop floor managers, supervisors, continuous improvement transformation change leaders, TPS specialists, individuals responsible for training and Organizational Development from all types industries and businesses who wish to lead more efficiently and are interested in creating a sustainable culture of Continuous Improvement through the use of management methodology of Toyota Kata.

Workshop Format

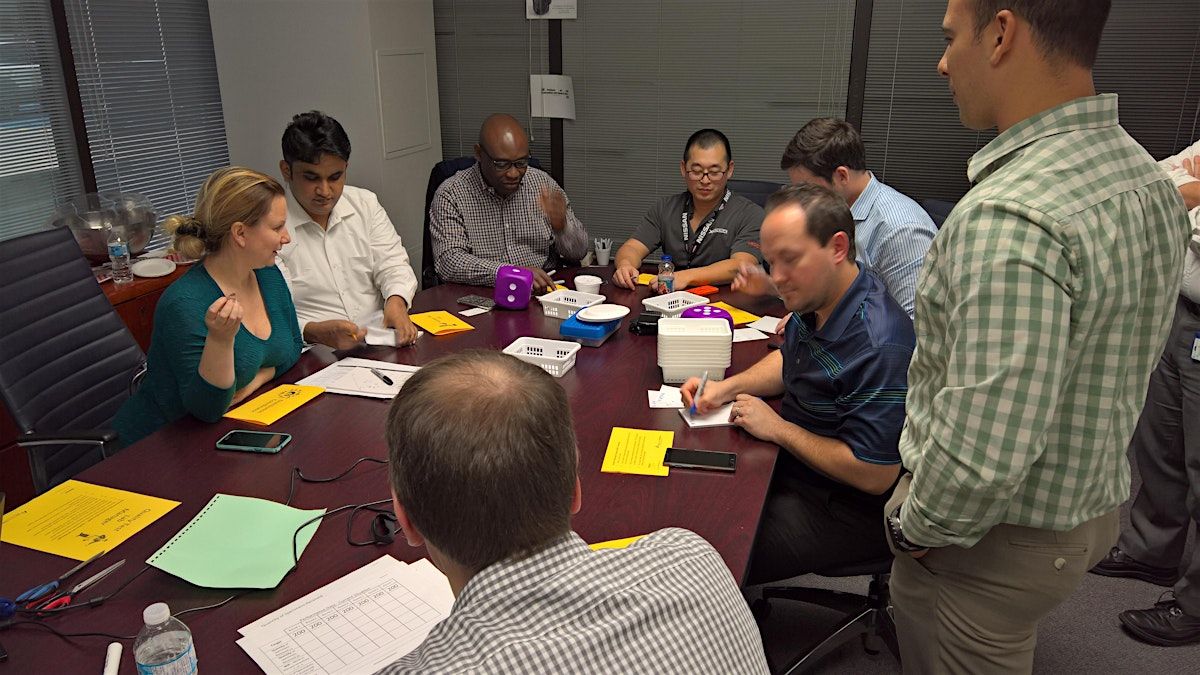

The work is a based on a Quality Lab Simulation. This is a Team Based activity, with six to eight participants per team. Each team will select their Manager (KATA Coach) and Team Leader (Learner) (Optional). Each Team will go through at least five rounds of simulating activities of a Quality Lab performing Hardness and Thickness testing on metal samples.

Prior to a first round of simulations each Team will identify and clarify their vision, directions and Target Conditions. Upon completion of each round the Team will work on identifying process improvements necessary to achieve the next Target Condition. How do we need to operate? What pattern of operation do we want? What obstacles (problems) do we need to overcome in order to achieve our next Target Conditions? How does the process need to behave …. to achieve the desired results.

Participants, Coaches (Managers) and Learners (Team Leaders) will gain direct insight into the power of the 5-Question Coaching Dialogue and Rapid PDCA Cycles through repeated personal practice. At the heart of the training experience is a challenge that requires a high level of ingenuity and continuous improvement, on the spot, in real time.

Event Venue & Nearby Stays

201 Bay St, 201 Bay Street, Midland, Canada

CAD 1237.35