About this Event

Description

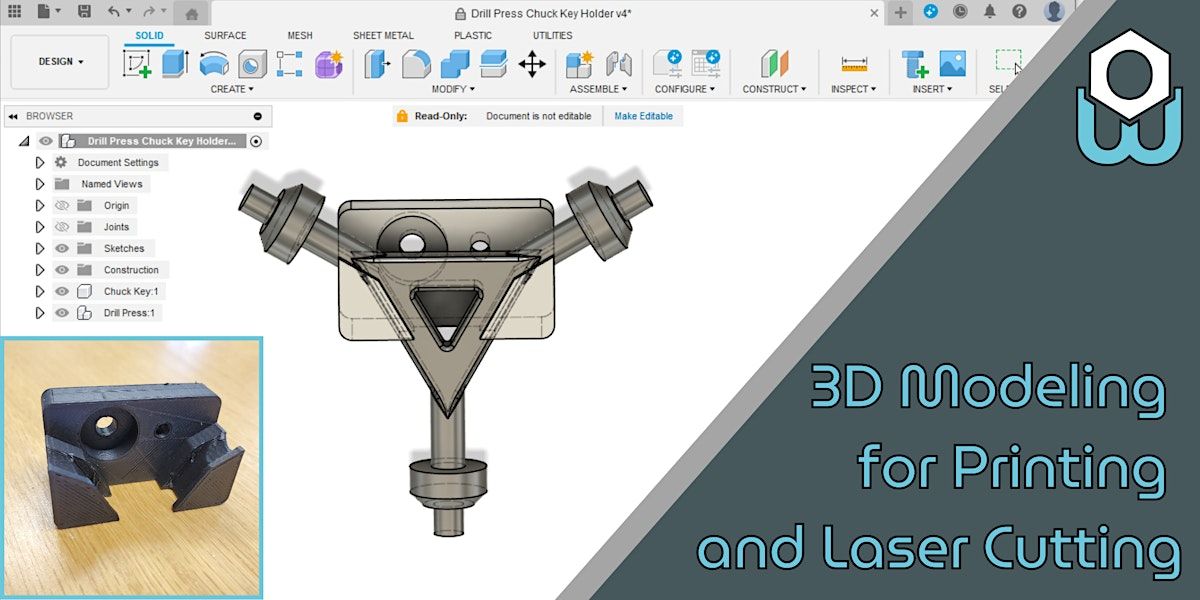

In this six-hour class series, you’ll start from the basics of CAD and work your way up, getting practice and hands-on experience along the way - finally culminating in 3D printing or laser cutting your own custom design!

In the first three-hour session, you’ll learn how three-dimensional objects are created and represented in CAD software, the benefits and drawbacks of digital parametric design, and why CAD is so prevalent in engineering. With the basics under your belt, you’ll boot up Fusion and learn about sketches, dimensions, constraints, and features, how to use those to create and modify simple 3D designs, and how to find help when you get stuck. We'll also discuss considerations when recreating and using a physical object in 3D modeling software, including critical dimensions, symmetry, and sketch projection.

Class attendees should leave this session with an understanding of CAD technology, the knowledge necessary to create simple three-dimensional designs in Autodesk Fusion, and the ability to locate resources to learn more when they reach the limits of that knowledge.

Prerequisites

- Experience using computers and desktop software is required for this class.

- A laptop and mouse are required for this class. Open Workshops has a limited number of laptops available to borrow on a first-come first-served basis. Please notify us via email at [email protected] if you wish to borrow a laptop.

- Attendees must to register for an Autodesk account and install Autodesk Fusion for Personal Use on their laptop or a home PC using the following link prior to attending the class: https://www.autodesk.com/products/fusion-360/personal

Both in-person and online registration is available for this class. Please read the description on each ticket type for details.

In the second three-hour session, you’ll dive deep into 3D modeling specifically for 3D printing and laser cutting. You’ll learn about orientation, support, overhangs, bridging, and other important considerations when designing a part to be 3D printed. You’ll also learn about stock thickness, front and side corners, tolerances, and other things to think about when designing a part for laser cutting. We’ll discuss how to produce files for each of those processes from Autodesk Fusion, take a look at a few examples of these principles in practice, and then you’ll get to try your hand at modeling for 3D printing - creating a design of your own to be printed on our Bambu P1S or cut from wood or acrylic on our 60W CO2 laser!

Class attendees should leave this session with the ability to take a simple design from an idea, through the 3D modeling process, and finally arriving at a physical item - whether laser cut or 3D printed.

Event Venue & Nearby Stays

Open Workshops, North Opdyke Road, Auburn Hills, MI, USA, United States

USD 33.85 to USD 97.88