About this Event

This event features two talks on corrosion relevant to the maritime sector and is a joint lecture with the Institute of Corrosion, Wales and South-West Branch.

Tackling Bracket Corrosion in Marine Boiler Superheaters: Challenges and Solutions

Bracket corrosion in superheaters of marine boilers is a serious concern. Superheaters are critical components of the boiler system, as they increase the temperature of the steam produced by the boiler, ensuring its efficiency in driving turbines. These components are subjected to high pressures and temperatures, making them prone to various types of corrosion, including bracket corrosion. This specific corrosion typically affects the supports or brackets that hold the superheater tubes in place.

This presentation will offer an insight into the potential corrosion mechanisms that can be encountered, focusing specifically on the various forms of degradation that can affect their structural integrity. From high-temperature corrosion and stress corrosion cracking to corrosion under insulation, each mechanism poses distinct challenges to boiler performance and safety. Through a detailed exploration of these processes, we will examine the factors that contribute to corrosion, such as water chemistry and operational stresses. Furthermore, we will discuss effective prevention strategies, including proper maintenance practices, advanced materials, protective coatings, and water treatment techniques, aimed at mitigating these risks and enhancing the longevity and efficiency of marine boilers.

Corrosion performance of wire and arc additive manufactured 316L stainless steel with and without stress-relief heat treatment

Wire and Arc Additive Manufacturing (WAAM), a Direct Energy Deposition process, is particularly suitable for the manufacturing of large metallic structures several metres in size. In recent years, the mechanical performance of WAAM-manufactured parts has been extensively studied. However, their corrosion performance has received only limited attention and needs further investigation since the maritime sector would greatly benefit from this new manufacturing process.

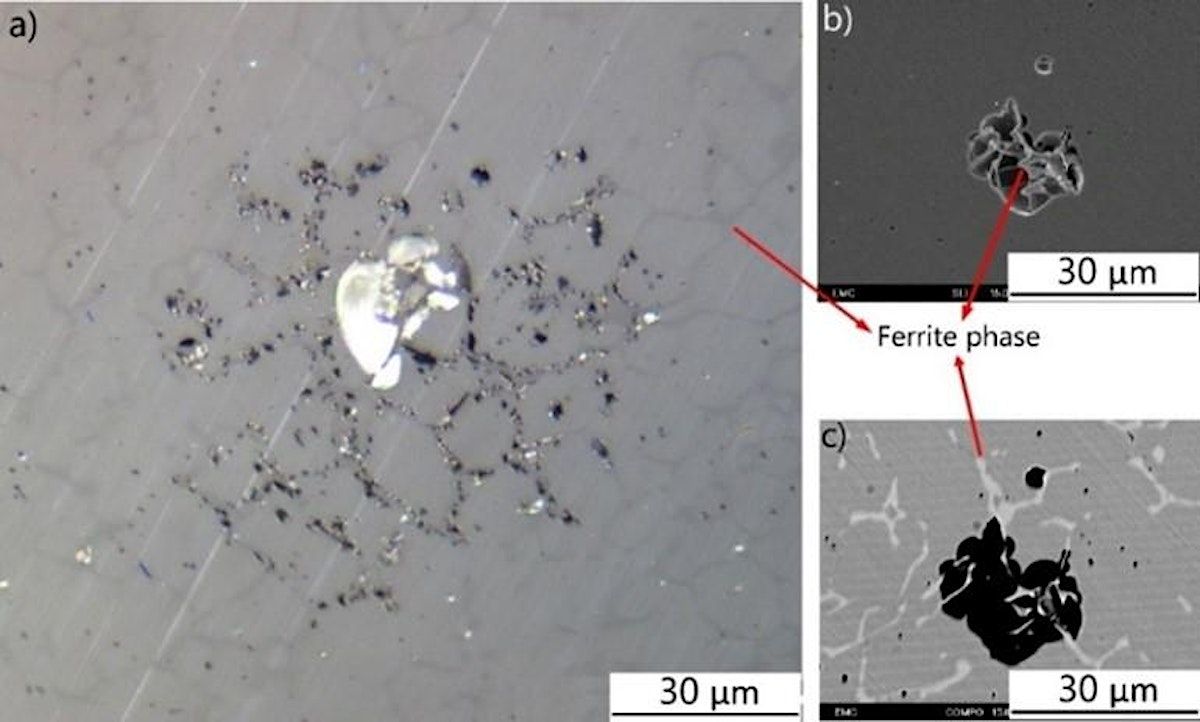

It is expected that such a microstructure will alter the corrosion behaviour compared to 316L SS manufactured using traditional methods. In this work, the corrosion performance of as fabricated and heat-treated WAAM 316L is investigated using potentiodynamic polarizations in a 3.5 wt.% NaCl test solution and compared with wrought 316L SS. The heat treatment consists of a two-hour dwell at 900℃ for stress relief and air-cooling at room temperature. Corroded surfaces were analysed using optical, scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDS).

About the speakers:

James McConnell is the Consultancy Manager at R-TECH Materials, leading a team of professionals that provide world-leading materials expertise. James has a degree in Materials Science and Engineering and has specialist expertise in the integrity and remnant life assessment of on/offshore steam plants and associated components. Over his career, he has conducted more than 200 failure investigations across a variety of plants, mechanisms, and materials, along with over 100 intrusive inspections of steam plants and large industrial boilers, across the globe.

With nearly a decade of experience in the offshore sector, James has gained valuable insight into the fabrication and installation of steam plant systems. He holds all necessary certifications to work in offshore environments, allowing him to provide metallurgical support on-site, enhancing his ability to offer comprehensive, hands-on expertise.

Julian Wharton is a Professor in Corrosion and Surface Engineering at the National Centre for Advanced Tribology (nCATS) research group at the University of Southampton. His research focus is the fundamental understanding of surface degradation of metallic materials, and interfaces in and between engineering materials and their environment. His work has pioneered understanding of interfaces under a combination of mechanical and environmental interactions, exploring the interplay between corrosion degradation and structural integrity, particularly for maritime structures.

Additional information:

This lecture is a hybrid lecture - if you would like to attend the Zoom lecture please follow the link below:

https://www.eventbrite.co.uk/e/joint-lecture-with-the-institute-of-corrosion-zoom-tickets-1114000488449?aff=oddtdtcreator

Event Venue & Nearby Stays

Palmerston Lecture Theatre, The Spark, Southampton Solent University, Southampton, United Kingdom

GBP 0.00